Best Hydraulic Cylinder Manufacturers in Pune, Chakan, Bhosari, Talegaon, Ranjangaon, PCMC - 2025

Universal Engineering is a well established hydraulic cylinder manufacturers in Pune, Chakan, Bhosari, Talegaon, Ranjangaon, PCMC. Our focus on innovative engineering enables us to develop exceptional, solution-based hydraulic components. With over 12+ years of experience in this industry, we have satisfied more than 500+ customers. We design unique hydraulic cylinders that deliver complete satisfaction to manufacturing clients across the construction, automobile, and machinery sectors.

Hydraulic Cylinder Suppliers, Dealers & Traders in Pune

Every product we deliver focuses on durability, precision, and high-performance standards. Our expert team provides prompt delivery service with exceptional customer assistance. Throughout our years in business, we have maintained a position of leadership in hydraulic engineering.

The Hydraulic Cylinder Manufacturers, Suppliers, Dealers, and Traders in Pune

Our operations in Pune involve hydraulic cylinder manufacturing, supply, and trading, with a strong focus on logistics and maintaining business relationships across the region.

- Custom Hydraulic Cylinder Design: Our cylinders come as custom solutions that fulfill distinct customer specifications. Every design under our control delivers both precision and custom solutions, whether for commercial industries or individual machinery needs.

- High-Quality Material Selection: Our hydraulic cylinder manufacturing exclusively uses materials of outstanding quality. The whole material procurement process includes rigorous testing with specific quality control standards to verify performance and ensure durability and protection against damage.

- Efficient Manufacturing Process: A modern production center containing advanced production equipment operates within our facility for performing efficient manufacturing processes. Modern factory methods utilized with contemporary technologies allow for the manufacturing of hydraulic cylinders with high standards and short production durations.

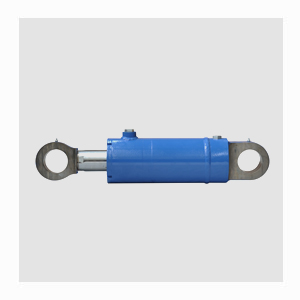

- Wide Range of Hydraulic Cylinders: We produce hydraulic cylinders that cover multiple industrial requirements through different specifications. Our product catalog contains single-acting mechanics together with double-acting compression cylinders that serve multiple industrial purposes beyond construction and automotive and agricultural needs.

- Comprehensive After-Sales Support: We deliver top-quality after-sales service, enabling consistent operation for their hydraulic cylinders. We assist customers with product installation combined with maintenance suggestions as well as rapid support for addressing their issues.

Types of Hydraulic Cylinders

Some of the Hydraulic Cylinder Manufacturers and Suppliers in Pune present an extensive range of high-grade cylinders that are flexible enough to be applied in all types as follows:

- Hydraulic Cylinder Tie Rod Construction: These cylinders depend on tie rods to bond their components while delivering stability and strength during operation. This design secures robust threaded rods to connect end caps with a cylinder barrel while enduring mechanical pressure.

- Industrial Hydraulic Cylinders: These cylinders serve industrial automation and machinery operations through force delivery and precise mechanical movements and are constructed for continuous use that extends their operational lifespan.

- Mill Duty Type Hydraulic Cylinders: Industrial steel mills operate their practical equipment with these cylinders since they have robust construction elements designed to work under challenging high-pressure conditions.

- Scissor Lift Hydraulic Cylinder: The cylinder delivers power to the vertical scissor lift platform system that can distribute stable forces for the control of lifting and lowering operations.

- Telescopic Hydraulic Cylinder: Multiple stacked stages within a single unit extend its operational distance in minimal space and find widespread application in dump trucks as well as lifting equipment.

- Hydraulic Press Cylinder: The tubing delivers enormous pressure for shaping or compressing materials, thus facilitating forging and stamping operations and forming tasks.

- Heavy Duty Hydraulic Cylinder: This device serves extremely challenging tasks that need powerful forces and maximum structural strength. These components operate regularly in construction sites and mining areas along with huge industrial machines.

- Mild Steel Mini Hydraulic Cylinder: This miniature cylinder built with mild steel materials suits short-term applications in compact machinery and restricted installation spaces.

- Double Acting Hydraulic Cylinder: The mechanical operation utilizes hydraulic power to perform extension and retraction movements of the piston, which enhances automated systems through improved control functions.

- Single Acting Hydraulic Cylinder: The only direction this hydraulic component operates comes from hydraulic force, but it returns to its original position through a spring system. The system performs basic linear motion functions at affordable costs.

- Small Hydraulic Cylinder: Compact in size, suitable for space-constrained operations. This device creates accurate motions and applies medium power to perform plain tasks.

Specifications of Hydraulic Cylinders

We have added below a technical sheet of our Hydraulic Cylinder that provides more technical information, such as:

| Specification | Hydraulic Cylinder Tie Rod Construction | Hydraulic Cylinder |

|---|---|---|

| Bore Size | 1500 mm | Upto 350mm |

| Hydraulic Pressure Ratings | 690 bar | 350 Bar |

| Material | Steel | Steel |

| Maximum Stroke | 2200 mm | 1000mm |

| Operating Pressure | 250 psi | - |

| Packaging Type | Carton Box | Wooden case |

| Temperature | 65 Deg Celsius | - |

| Fluid Type | Hydraulic Oil | - |

| Acting Type | Single and Double Acting | - |

| Usage/Application | Industrial | - |

| Bore Diameter | 350 mm | - |

Benefits of Hydraulic Cylinders

Being one of the very best in the category of Hydraulic Cylinder Suppliers and Dealers in Pune, all types of cylinders are made using advanced technology and hence offer a variety of benefits such as:

- High Power Output: The force output from hydraulic cylinders enables the operation of heavy loads through small equipment, thus making them suitable options for industrial and construction activities.

- Precise Control: These systems achieve precise positioning and smooth motion control because they play an essential role in automated systems operations.

- Durability and Reliability: When properly serviced, hydraulic cylinders have the potential to maintain their lifetime of numerous years by enduring harsh environmental conditions alongside heavy operational requirements.

- Versatility: Hydraulic cylinders demonstrate versatile capabilities that allow their application in manufacturing and mining operations and agricultural work because they perform lifting operations, pressing implementations, and pushing tasks.

- Efficiency in Energy Use: Powerful hydraulic system movements generated from hydraulic fluid transformations lead to reduced operational expenses during an entire operating cycle.

Applications of Hydraulic Cylinders

As Hydraulic Cylinder Dealers and Traders in Pune, our Cylinders are highly demanded for multiple types of applications used for improving performance, such as:

- Construction Equipment: These cylinders operate as controls for the arms, buckets, and booms within various construction equipment, including excavators, bulldozers, and cranes, to accomplish precise digging and heavy lifting operations.

- Manufacturing Machinery: Factory automation occurs when these cylinders activate presses and robotic arms alongside conveyors to do metal-forming work, assembly duties, and stamping functions.

- Agricultural Machinery: Farm equipment productivity relies on hydraulic cylinders because these cylinders operate the required lifting motions of plows, loaders, and other related attachments.

- Aerospace Applications: Aircraft landing gear systems, together with wing flaps, rely on hydraulic cylinders to provide dependable actuation functions across entire flight phases while supporting crucial system features all through landing operations.

- Automotive Industry: Hydraulic cylinders function inside car lifts and brakes and suspension systems by providing elastic element control of multiple mechanical parts to enhance maintenance processes together with vehicle operational functionality.

We are the Hydraulic Cylinder Manufacturers in Pune, Chakan, Bhosari, Talegaon, Ranjangaon, PCMC. Universal Engineering maintains an excellent position through its lineup of long-lasting, efficient products designed for commercial applications. We provide accelerated shipping benefits to fulfill customer needs in order to become a leading choice for businesses that require premium hydraulic cylinders. Contact our team to address all hydraulic requirements and access premium service platforms.

FAQ

The three main types of hydraulic cylinders are tie-rod cylinders, welded cylinders, and telescopic cylinders. Each type is used based on space, pressure, and application needs.

Hydraulic oil (typically mineral-based or synthetic) is used in hydraulic cylinders, with common types like ISO VG 32, 46, or 68, depending on the system’s requirements and operating temperature.

The purpose of a hydraulic cylinder is to convert hydraulic energy into linear mechanical force and motion, used to lift, push, or pull loads in machinery.

A hydraulic cylinder is a mechanical device that uses pressurized hydraulic fluid to create linear motion and force.